SQIDEP performance TESTING - litter basket

WHAT IS SQIDEP LABORATORY TESTING?

The Stormwater Quality Improvement Device Evaluation Protocol (SQIDEP) released by Stormwater Australia was supplemented in 2025 with a draft protocol for laboratory testing of devices, following field experience identifying specific hurdles associated with the random variability of nature. Founded on the British Water and ASTM E3332 Test Methods, the SQIDEP Lab Pathway provides a robust, repeatable and rigorous methodology to demonstrate "proof of concept" under controlled conditions, before installation in the field (uncontrolled conditions).

LITTER BASKETS

Litter Baskets are a proven method to capture gross pollutants (eg. trash >5mm) and coarse sediment, and many systems are implemented globally, in small catchment situations. Most technologies will perform a beneficial reduction of nutrients via capture of leaf matter and sediment, but this is often not quantified. As an important part of a stormwater treatment train, litter baskets can protect filters, wetlands and bioretention systems from being overwhelmed with trash and coarse sediment load. They can also provide some reduction to overall stormwater treatment areas required to achieve water quality objectives.

LITTER BASKET TESTING

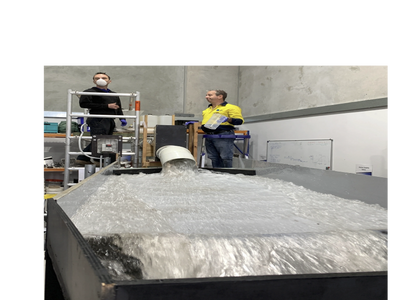

In collaboration with Pipe Management Australia, with independent third party supervision by QUT, Waterlabs Australia used our flat-bed test rig to undertake a variety of tests to identify the water quality improvement and litter capture capabilities of a new litter basket prototype.

PROJECT OUTCOMES

The litter basket prototype was proven to capture and retain litter up to 40 L/s, and remove notable levels of TSS, TN and TP given the limited treatment functions provided by the technology. Testing also identified challenges with transferring ASTM E3332 in Australian conditions, and incompatibility with the SQIDEP lab protocol.

CROSS RIVER RAIL FLOOD BARRIER SEAL TESTING

WHAT IS THE CROSS RIVER RAIL?

The Cross River Rail is a significant infrastructure project for Queensland involving 10.2 km of new rail line and 5.9 km of twin tunnels under Brisbane City and River. Brisbane is known as a city built on a floodplain, and so ensuring the new tunnels are protected from flooding is a priority.

FLOOD BARRIERS

Flood Barriers are a proven method to minimise the amount of water entering an area, and many property scale systems are implemented globally, in emergency situations. Large Pedestrian accesses to the Cross River Rail tunnels and stations required similar protection.

SEAL TESTING

In collaboration with Projex Partners and QUT, Waterlabs Australia designed a test rig to undertake a variety of tests to identify appropriate seal plasticity, durability and waterholding properties.

PROJECT OUTCOMES

Seals were proven to successfully minimise water ingress to an acceptable level. Optimal seal plasticity and durability were identified.

HUMEFILTER TESTING TO NJDEP FILTER PROTOCOL

WHAT IS THE NJDEP FILTER PROTOCOL?

The New Jersey Department of Environmental Protection (NJDEP) published a Laboratory protocol to assess the Total Suspended Solids Removal by Filtration Devices, with the latest update released on April 25, 2023. Manufacturers of new stormwater treatment technologies wishing to be implemented in New Jersey must be tested and verified against the Protocol. A link can be found here (https://dep.nj.gov/wp-content/uploads/stormwater/filter-protocol-04252023-final.pdf) Many surrounding US States also rely on the NJDEP verification as a minimum benchmark for use.

SEDIMENT FORMULATION

The NJDEP Filter Protocol has a very specific particle size distribution (PSD) and requires that the media consist of silica sand. Waterlabs has developed the required blend to produce the PSD with available silica in the Australian market.

REMOVAL EFFICIENCY TESTING

Two Humefilter models were tested to satisfy the NJDEP protocol requirements for demonstrating scaling relationships. The UPT1200 was tested at 12 L/s, and the UPT1800 was tested at 30 L/s.

The NJDEP Filter Protocol requires a minimum of 10 test runs at the design treatable flow rate (MTFR) to demonstrate cumulative suspended solids reduction of >80%.

MASS LOADING CAPACITY

Once the minimum of 10 test runs are performed, the technology is then tested to identify the maximum capacity of sediment it can retain prior to failure. This can be a handful of test replicates, or many multiples, depending on the technology.

PROJECT OUTCOMES

The Humefilter UPT1200 was successfully proven to remove >90% suspended solids at its MTFR, and was Verified by NJDEP for 80% in March 2025, in accordance with their maximum reduction limit.

PRODUCT DESIGN AND DEVELOPMENT

We aim to help clients bring their ideas to life. Our team of designers and engineers has experience in various industries and can provide effective solutions that meet your requirements. It is our desire to help clients get the best outcome possible from their prototypes, and we provide feedback from our decades of experience designing, testing and delivering treatment technologies. Product development is an iterative process, so our goal is to assist in reducing those iterations and costs for our clients.

PROTOTYPE TESTING FOR PFAS REDUCTION

WHAT IS PFAS?

PFAS is a family of very stable, long-lived chemicals (Per- and polyfluoroalkyl substances). They were traditionally used in Aircraft Fire Fighting Foams (AFFF) because they very effectively extinguished fires where liquid fuels were involved. But they also occurred in many everyday items that used Scotchgard, water-proofing sprays, Teflon (non-stick) cooking utensils and many others.

WHAT ARE THE RISKS?

Multiple health effects have been linked to PFAS exposure (Lewis RC, Johns LE, Meeker JD. 2015. Serum Biomarkers of Exposure to Perfluoroalkyl Substances in Relation to Serum Testosterone and Measures of Thyroid Function among Adults and Adolescents from NHANES 2011-2012. Int J Environ Res Public Health. 12(6): 6098-6114.), and their longevity means that they can accumulate over time.

TREATMENT OPTIONS

Our client has developed a treatment technology aimed at reducing PFAS significantly below initial dosed concentrations. They engaged us to develop a test rig, and determine the reduction capabilities of the technology.

TESTING PROTOCOL

Waterlabs constructed a test rig, prepared PFAS doses for introduction into various flowrates and collected samples at the inlet and outlet, for laboratory analyses. All treated effluent was responsibly collected and disposed of by a licensed liquid waste contractor.

OUTCOMES

Testing proved conclusively that the technology reduces PFAS concentrations at reasonable flowrates.

WORKPLACE HEALTH AND SAFETY

Given the risks associated with PFAS and testing with large volumes of water, we implemented multiple risk management measures for our team.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.